Ceiling light boxes manufacturing:

Introducing our ceiling light boxes – the perfect lighting solution for auto 4S shops, showroom garages, and car detailing centers.

Our ceiling lightbox is designed to provide bright and even lighting, ensuring that every detail of your car is highlighted. With their sleek and modern design, our light boxes will not only enhance the look of your space but also provide a comfortable and inviting atmosphere for your customers.

Our ceiling light boxes are easy to install and maintain, making them the perfect addition to any space. Plus, with their energy-efficient LED technology, you can save on your electricity bills while still enjoying high-quality lighting. Don’t settle for ordinary lighting – elevate your auto 4S shop, showroom garage, or car detailing center with our ceiling light boxes.

Ceiling light boxes parameters:

| Item Code | ZG/E1013 | ||

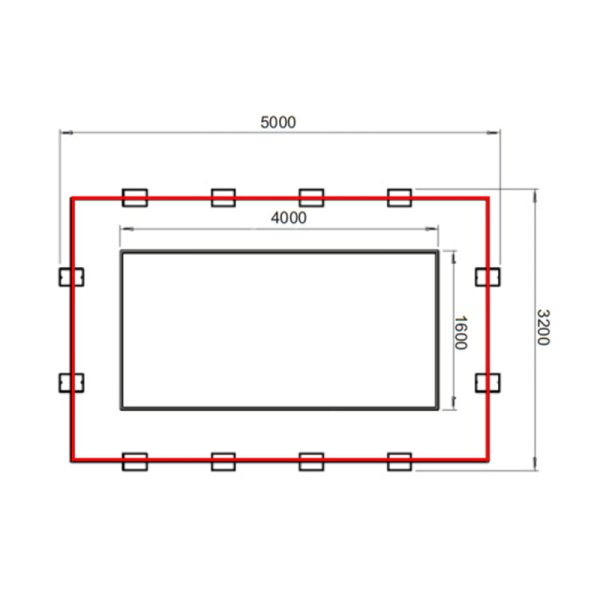

| Space Size | W3.2m*L5m*H0.1m | ||

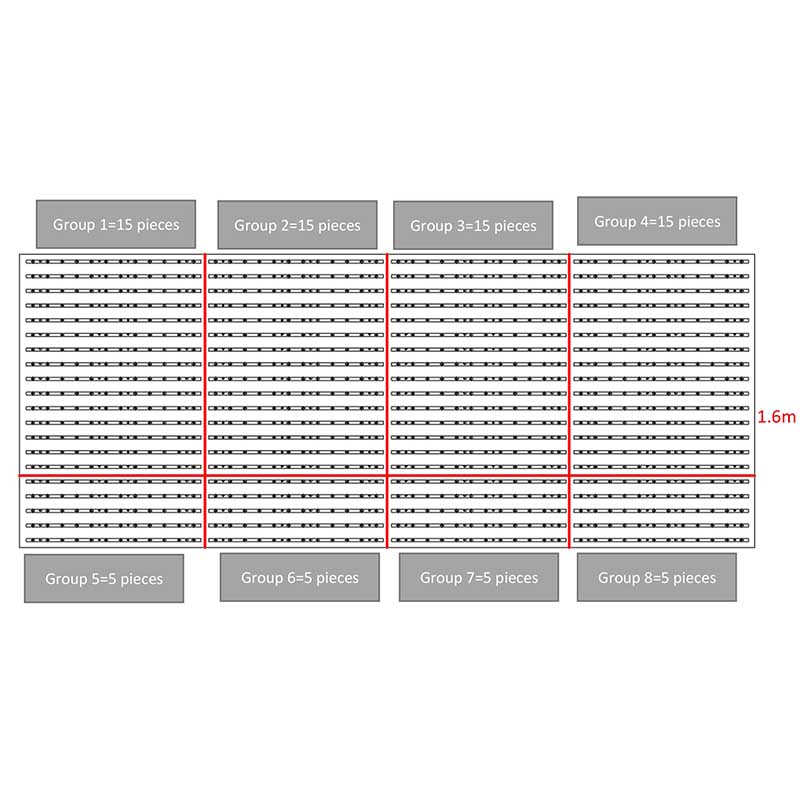

| Qty/SET | 12 pcs color matching lights + 1.6*4m lighting box | ||

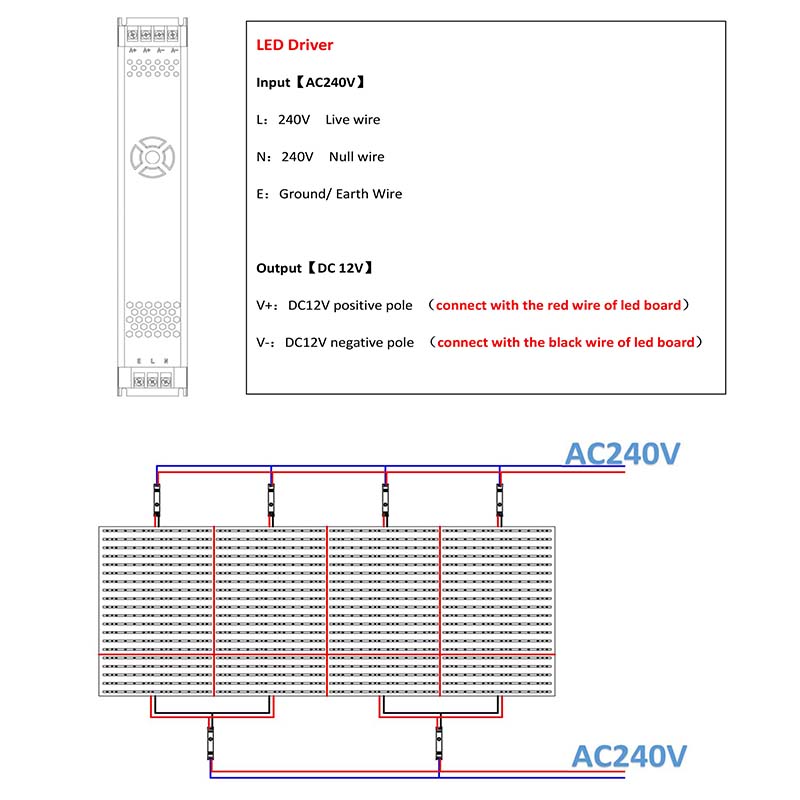

| Parameters | Voltage | AC100-220V | |

| Power | 1000W | ||

| Luminous Flux | 110-120lm/w | ||

| CRI. | >70 | ||

| CCT. | 6500K (White) | ||

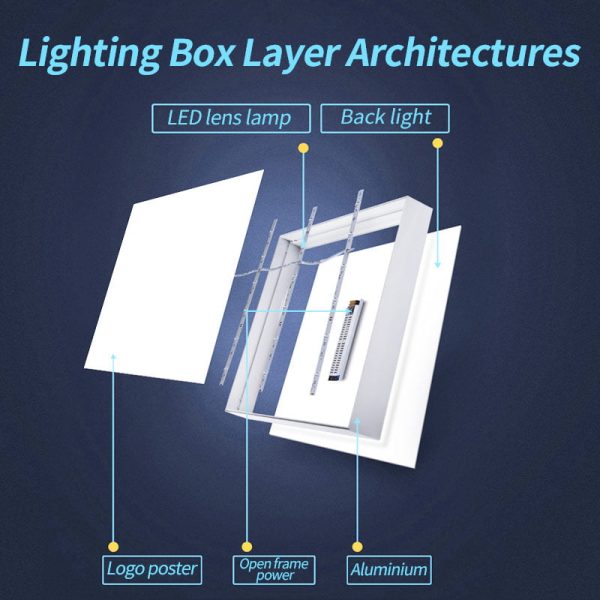

| Material | Aluminum + UV Film | ||

Remarks:

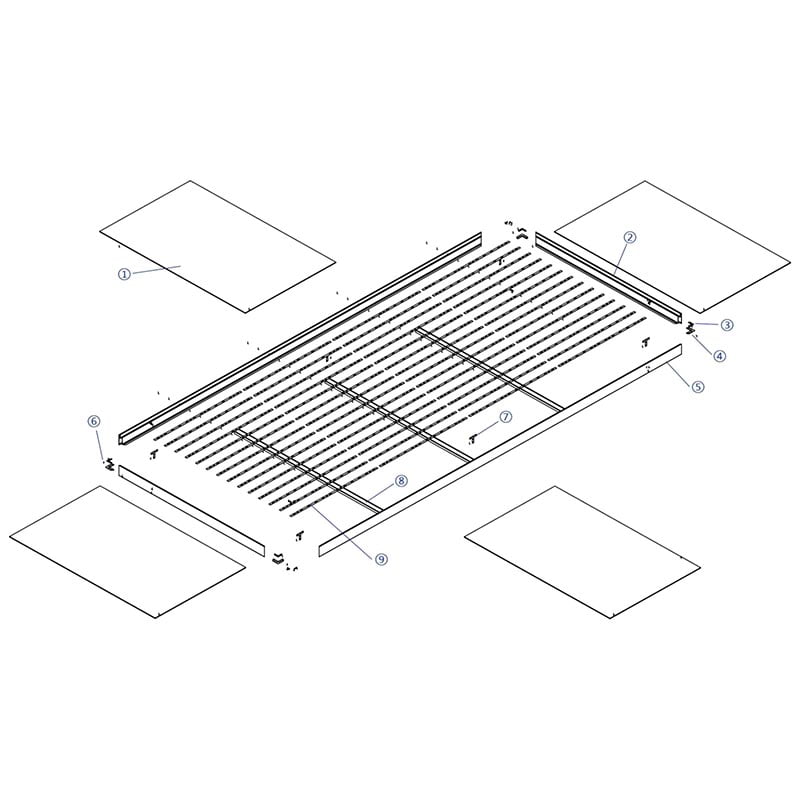

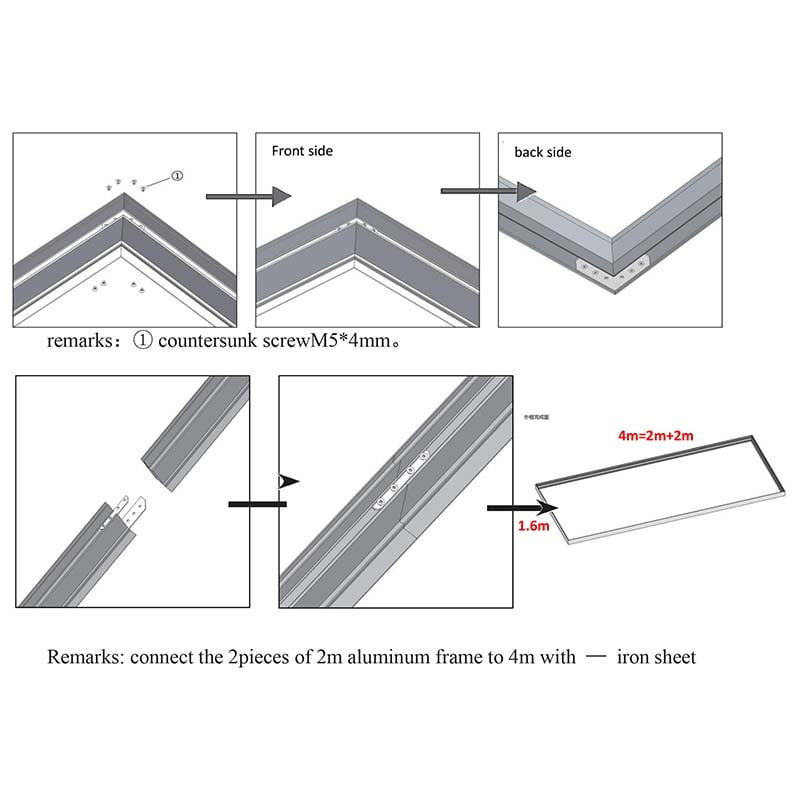

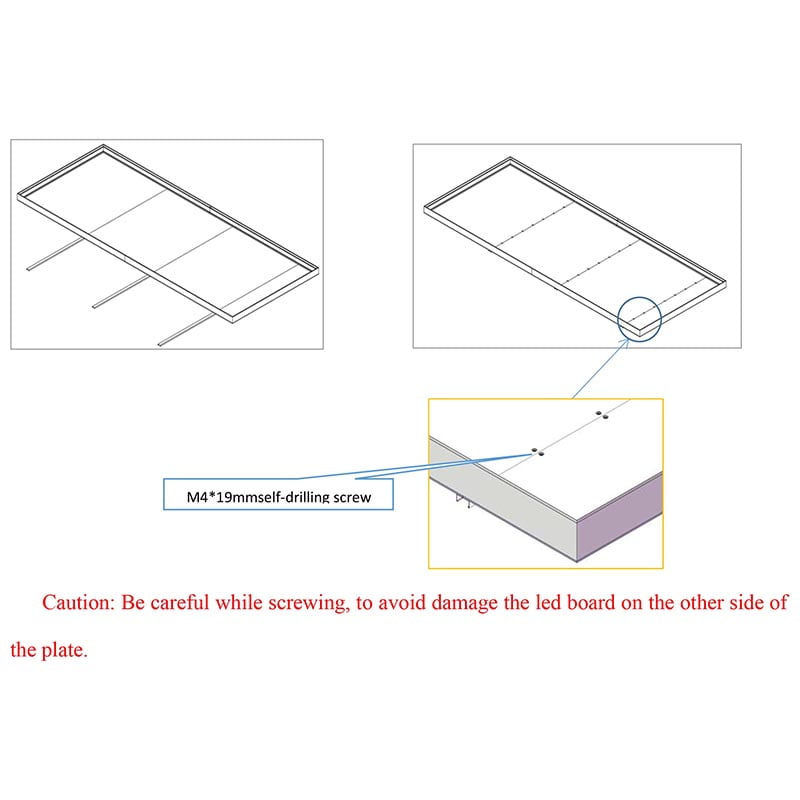

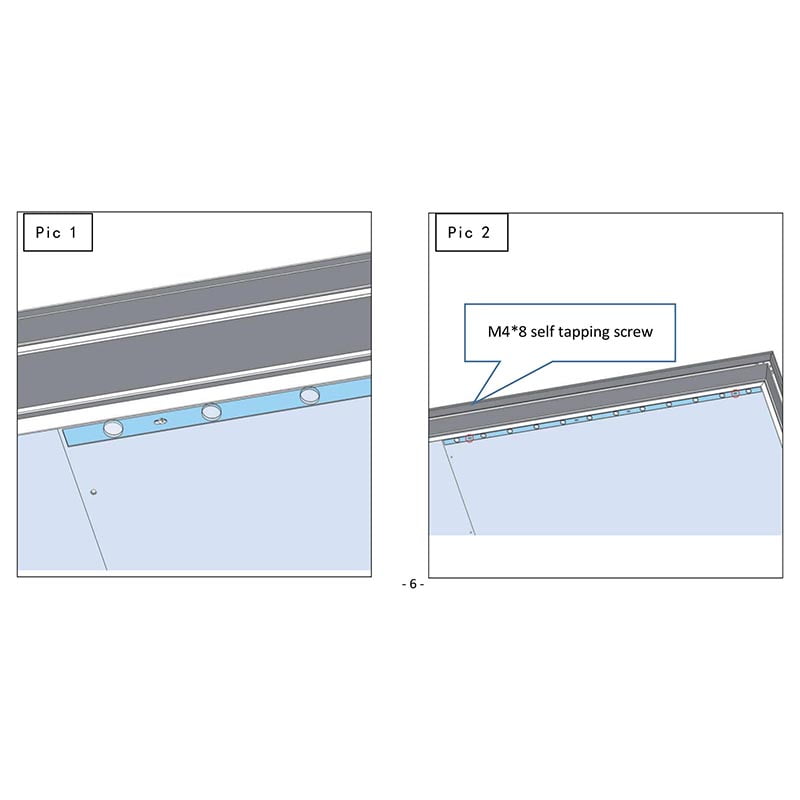

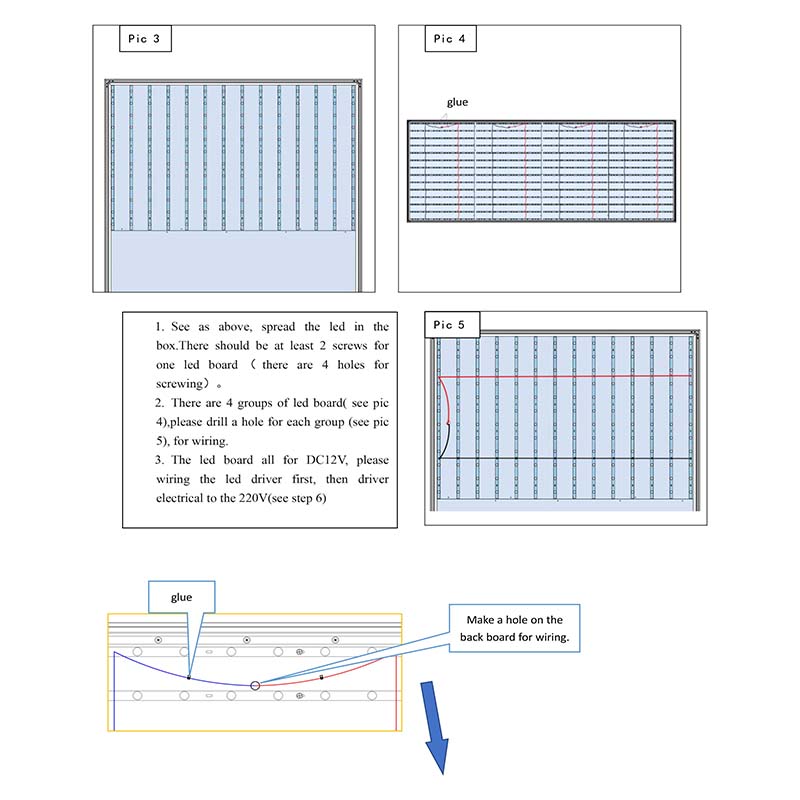

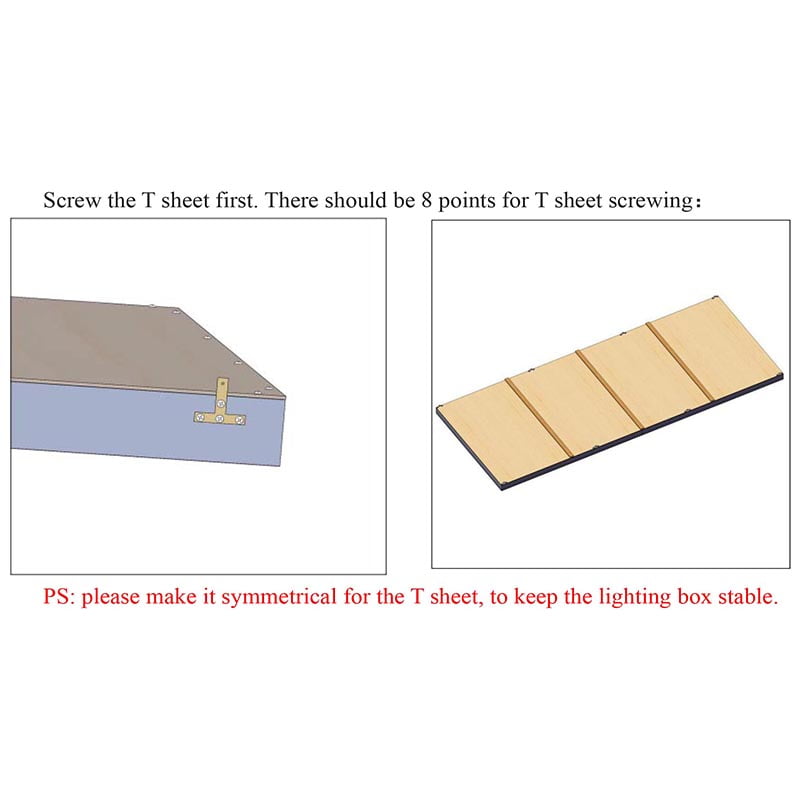

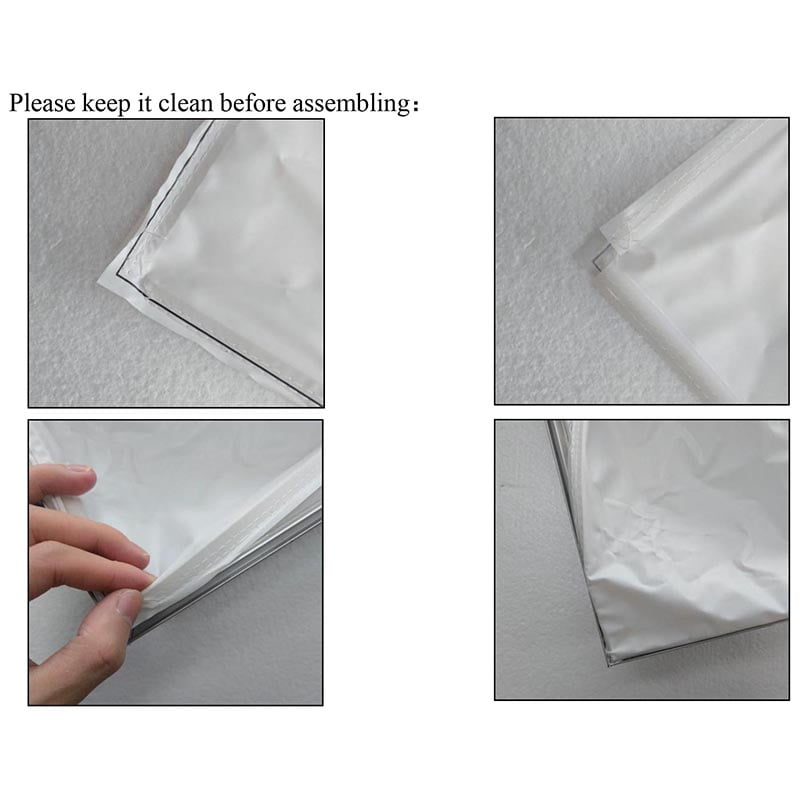

1. Pls prepare an 8mm fireproof plate for assembling;

2. Parts list: 12 pcs color matching lights (3 colors) + 1.6*4m lighting box (without plate)

3. Color-matching light frame, not included.

Application:

Ceiling box lighting is versatile and can be used for a variety of scenes, including automotive shops, auto body shops, auto detailing shops, auto repair shops, car wash shops, workshops, garages, showrooms, gyms, ceiling, gaming, wall, barber shop, supermarket and more.

Function:

1. Ceiling light boxes are professional, providing high illumination, non-flickering lighting, non-glare, and non-shadow effects, which protect the body paint color from distortion.

2. A color temperature range that is most suitable for construction is adopted, reducing visual fatigue for maintenance personnel and enhancing the natural beauty of the car.

Advantages:

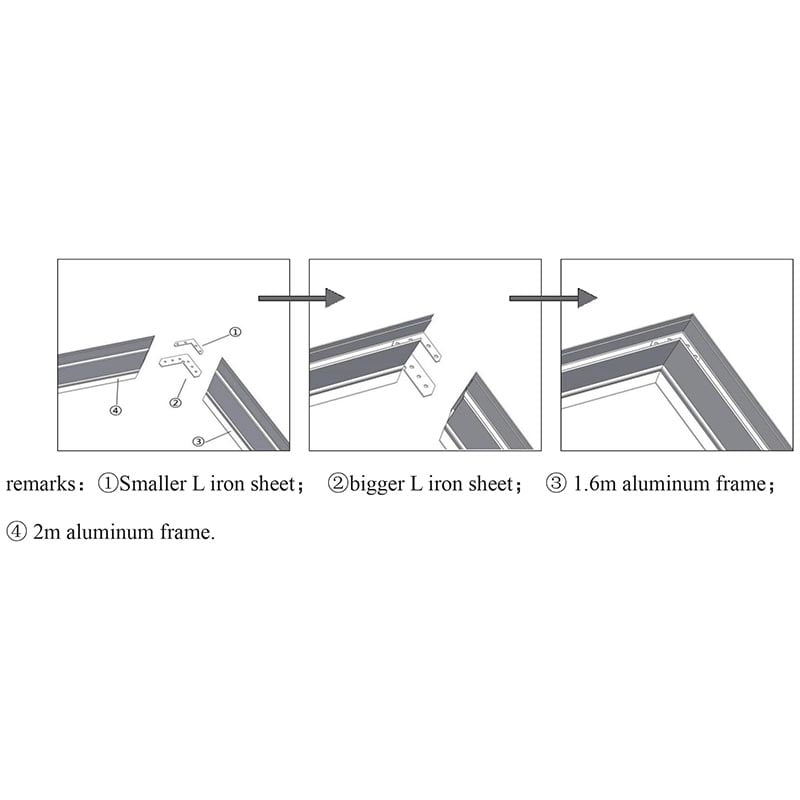

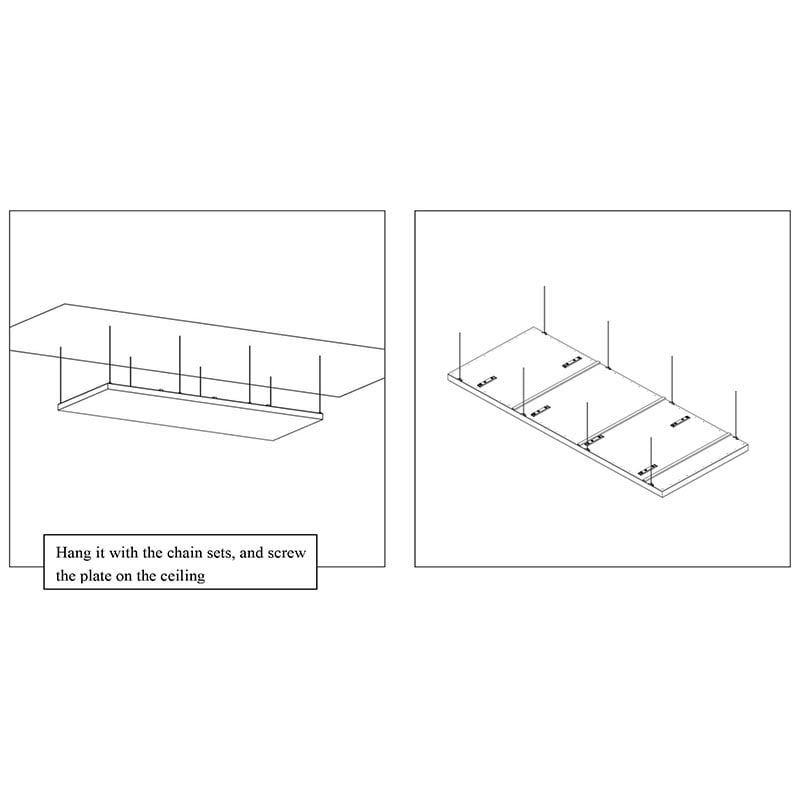

1. Easy to install: These ceiling box lighting can be surface-mounted or suspended from the ceiling, providing convenient overhead task lighting. They can be directly fixed to the ceiling with screws or easily installed with mounting brackets.

2. DIY assembly design: You can assemble them yourself, unleash your imagination, and create various patterns that you like.

3. Cost-saving: With standardized factory production, installation instructions, and video demonstrations, customers can save more than 60% on labor and capital investment compared to traditional decoration.

4. Personalized custom design: We support size customization to meet your personalized needs.

5. Provide CAD drawings and professional ceiling light panels supplier lighting solutions: Customers only need to provide site dimensions and our sales engineers can design lighting adjustments, and provide structural layout drawings, or 3D renderings.

Our production capacity is

6,000 pieces per day.

OEM/ODM manufacturing capability:

We have a professional automotive beauty lighting team. We are a manufacturer of automotive beauty lighting that integrates research and development and production. We also have a united, mature, and highly standardized R&D team. We continuously challenge ourselves in the field of product innovation, striving to provide customers with innovative and reasonably designed automotive beauty lighting.

Our commitment:

We are an ODM/OEM manufacturer, and our ceiling light boxes are customer-centric. Our products are designed to industry standards and are durable. We provide high-quality products and services customized to meet your personalized needs and ensure that your project has the best products and support.

Common search terms:

Ceiling light boxes, ceiling box lighting, light ceiling box, light box ceiling, box LED light for ceiling